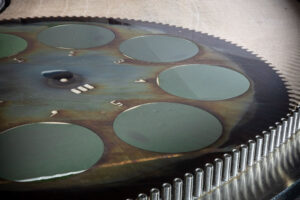

Lapping, Polishing, and Grinding Carriers

We manufacture lapping carriers (also called workholders) for planetary lapping and polishing machines including those manufactured by P.R. Hoffman, Speedfam, Peter Wolters AG, Hamai, Somos, Fujikoshi, Strausbaugh, Melchiorre, Lanzhou, Lapmaster and other specialty machines adapted for unique applications. Lapping carriers are available in a variety of materials and thicknesses, including an inventory of more than 20 spring steel thicknesses.

We can create a custom drawing that you can review to ensure the design meets your exact specifications. If you have a drawing or sample part for a lapping or polishing process, PR Hoffman can provide a detailed quotation for your review.

PR Hoffman uses a wide variety of state of the art manufacturing methods to create your lapping carriers including, precision punching, Wire-EDM cutting, CNC machining, CNC routing, and laser cutting. With these options, nearly any lapping carrier configuration is available. We will recommend the most cost-effective method based on your machine and volume requirements.

Carrier Features

- The wafers are afforded greater freedom of rotation with reduced edge damage which helps improve TTV

- 100mm – 450mm Wafer size

- Reduce Cost of Ownership

- Customer Design for your specific application

- ISO 9001:2015 Certified

- Recognized as Worldwide Supplier

- Precision Thickness Control

Details

Spring Steel

Spring Steel

Spring steel is the strongest and most durable carrier material. The tightest flatness and thickness tolerances are available in PR Hoffman Steel Carriers.

Cold Rolled Steel

Excellent for thick sturdy parts.

Blue Steel

Primary used for small carriers running thin parts.

Stainless Steel

Perfect for polishing applications that require corrosion free process

G-10 / FR-4

Fiberglass reinforced epoxy. Excellent alternative to steel. Use in applications that prohibit steel but still requires a carrier with strength and durability

Phenolic

Linen, canvas or paper reinforced phenolic resin. Use in processes that cannot tolerate the fiberglass but requires some carrier strength. Best suited for use with oil-based slurries.

PVC

Less costly option for thicker carriers. PVC offers chemical inertness and high strength to weight ratio.

Polycarbonate

Small Carriers for use in nonabrasive environment, reduced strength but also reduces scratching of reinforced alternatives.

Vinyl

Small Carriers for use in nonabrasive environment. Used primarily for short quick runs on small machines.